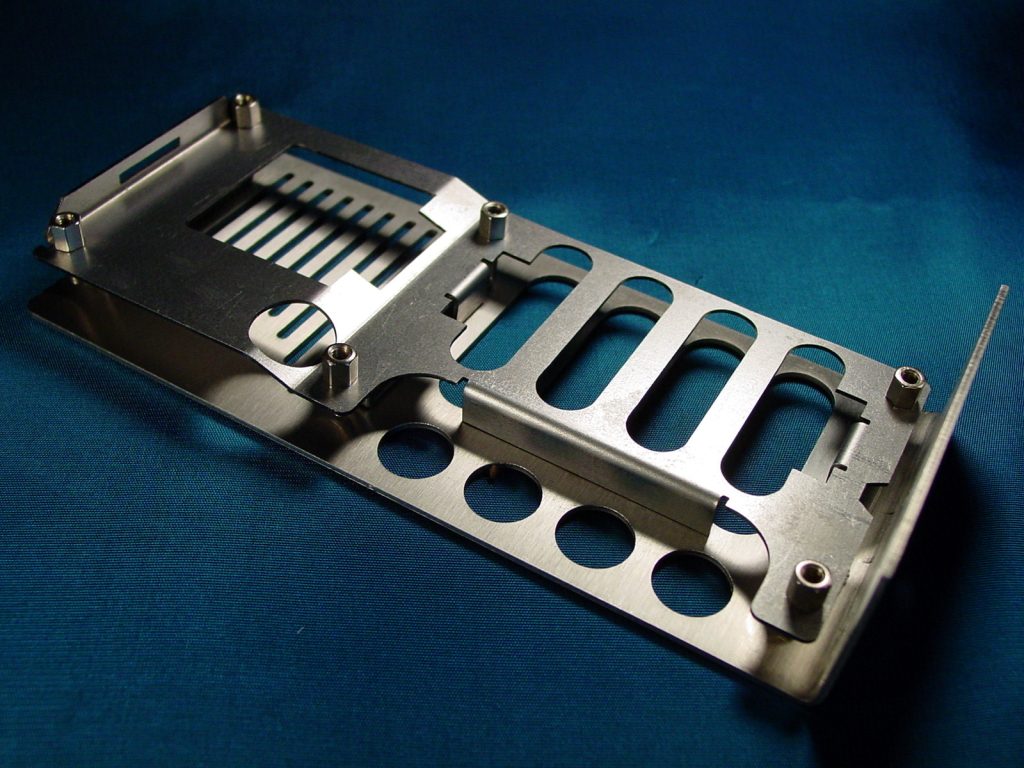

Turn components into precisely welded assemblies with peform.

We integrate laser- and water-jet-cut and machined components into finished welded assemblies that precisely meet your technical specifications. From simple connections to complex assemblies, we deliver quality that meets the highest industry standards.

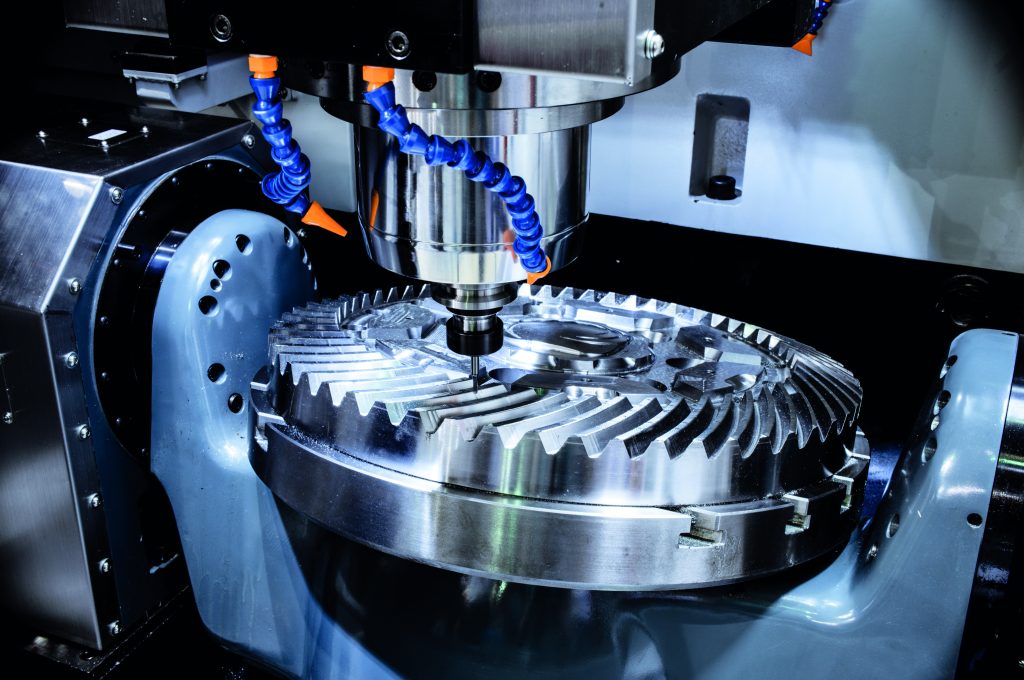

Technology

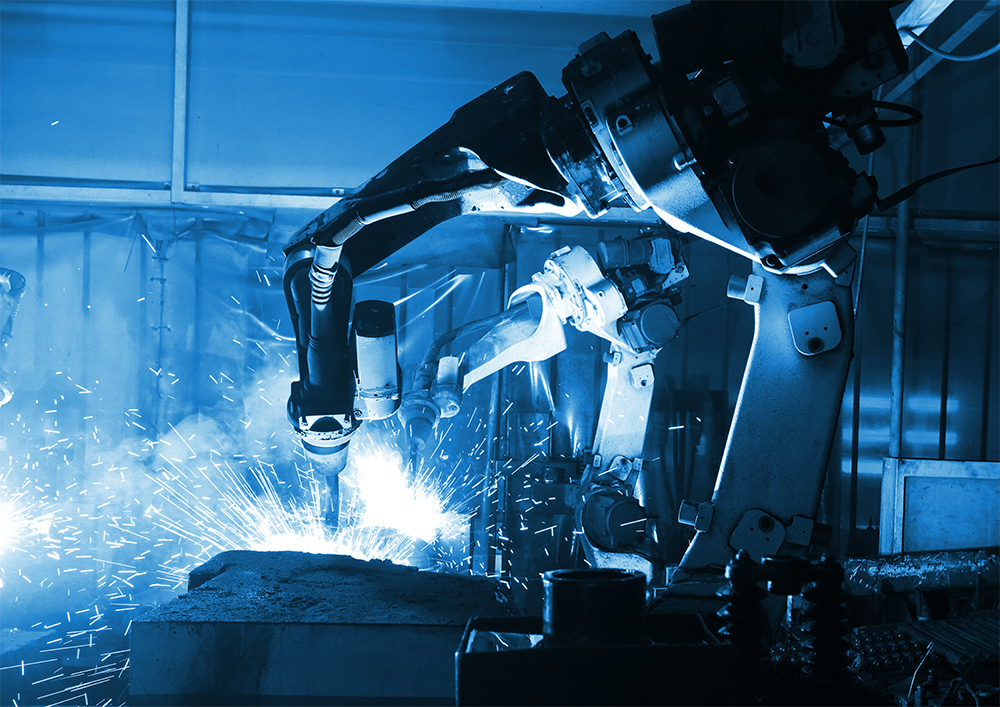

Highly developed welding technologies for demanding requirements. Our welding capabilities combine advanced robotic and skilled manual processes. We utilize MIG, MAG, and TIG technologies for manual welding, supported by automated MIG robotic systems. All processes comply strictly with European welding standards, ensuring consistent quality across every project.

Achieve optimal strength and precision in every welded assembly.

Whether your project demands the precision of TIG welding or the efficiency of MIG/MAG processes, we deliver tailored solutions. Our expertise ensures both strength and performance, meeting exact specifications for quality and reliability.

Why peform?

- Comprehensive expertise across multiple welding processes

- Advanced robotic capabilities for consistent quality

- Certified compliance with European welding standards

- Flexible capacity for small and large assemblies

- In-house quality control and testing

- Seamless integration with cutting and forming services

Main technical specification

- TIG welding: Carbon and stainless steel (1–6 mm thickness)

- MIG/MAG welding: Materials 1.5 mm and thicker

- Assembly size: Up to 2x2x3 meters

- Assembly weight: Up to 800 kg

Would you like to have something manufactured with this technology?

Find the peform location that realizes your challenge.

Find Location