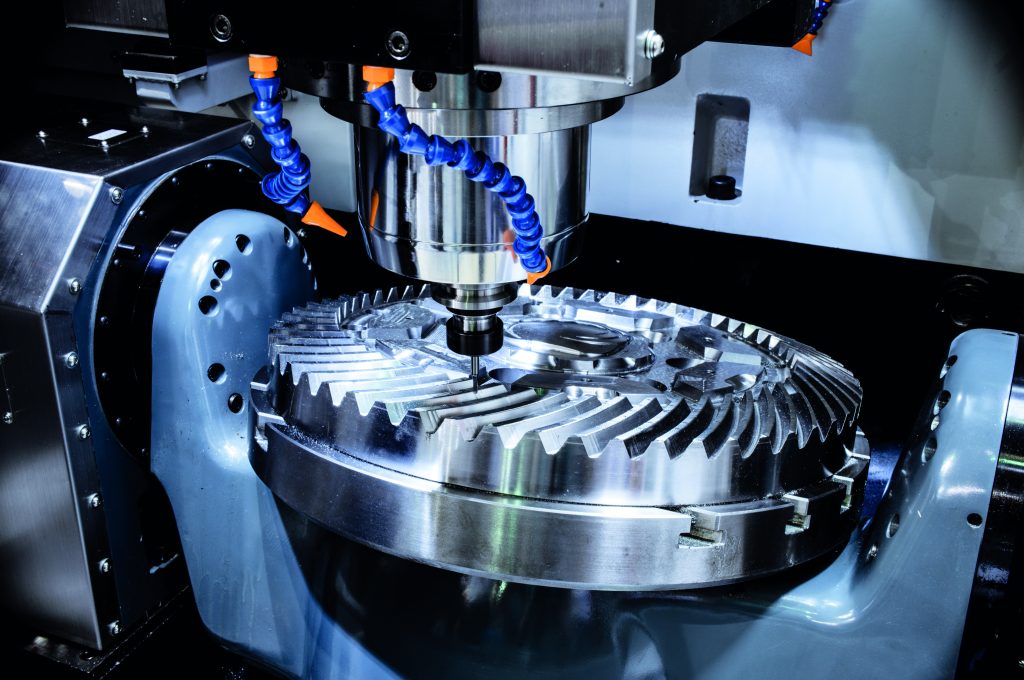

Enhance your component quality with peform’s precision surface grinding solutions.

Our surface treatment provides high-quality finishes for semi-finished and finished products, ensuring optimal preparation for further processes or compliance with final specifications (for visible parts). As an integral part of our manufacturing, we ensure consistent quality at every stage of production.

Technology

We combine automated and manual grinding processes, utilizing advanced deburring machines and specialized belt grinders. From hardened metals to plastics, castings, and forgings, we achieve precise surface specifications through carefully controlled operations tailored to diverse material needs.

Benefit and application

Surface grinding plays a dual role: as a critical intermediate step for subsequent processes and as a final finishing touch, ensuring optimal quality and aesthetics. This versatile capability meets the exact requirements of various industries, enhancing the functionality and appearance of finished components.

Why peform?

- Integrated grinding solutions within the complete manufacturing process

- Customized surface finishes for small batch and individual production

- Expert consultation for optimal production methods

- Long-term customer relationships built on consistent quality

- Flexible processing capabilities for diverse material types

- Comprehensive quality control system

Main technical specification

- At peform Chomutov, the deburring machine processes components up to 1100mm wide with a 250mm working stroke.The system features four processing units, including two grinding stations, a brush unit, and a roller unit.

- The peform Brumov facility handles non-rotary parts up to 2000 x 800 x 600mm with a maximum weight of 3000kg. For rotary components, we accommodate parts up to 450 x 630mm, weighing up to 1000kg.

Would you like to have something manufactured with this technology?

Find the peform location that realizes your challenge.

Find Location