Transform your manufacturing challenges into precision-engineered solutions with peform.

Using advanced forging technology, we create exceptional components tailored to your needs. Our sites in Chrudim and Vitanje combine decades of expertise in the development and production of forged blanks and machined components that meet the highest quality and performance standards.

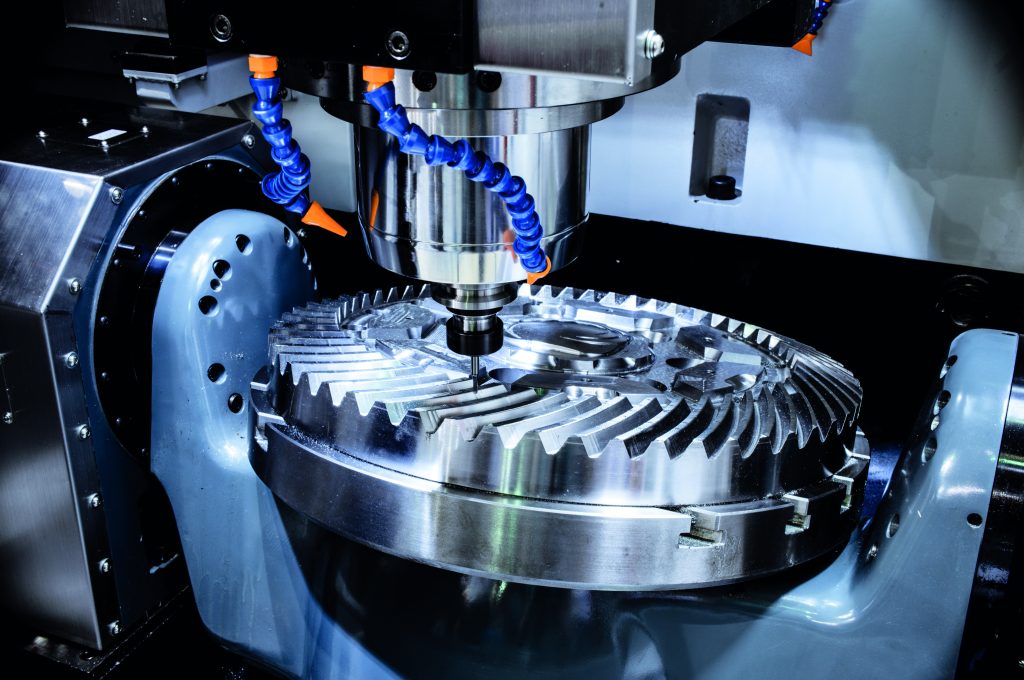

Precise forging processes for maximum accuracy.

Our forging process leverages advanced Lasco hammers with controlled strokes for precise warm and cold trimming. We specialize in precision drop forging of steel and aluminum alloys, achieving remarkable accuracy of ±0.2 mm. Our comprehensive services cover everything from raw material processing to final product finishing.

End-to-end solutions for maximum efficiency.

By combining advanced simulation technology, comprehensive quality control, and experienced staff, we deliver end-to-end solutions. From design to finished products, we simplify logistics, reduce costs, and deliver superior components. Industries such as automotive and rail, mechanical engineering, agriculture and medicine benefit from our durable and high-performance forged products.

Why peform?

- Over 60 years of expertise in steel forging and 45 years in aluminum forging

- State-of-the-art machining and proprietary tooling production knowledge

- Extensive certifications (ISO 9001, ISO 14000, ISO 45001, ISO 50001)

- Consistent high quality and reliability

- Advanced simulation software and in-house engineering enable flexible production and customer specification

Main technical specification

- Maximum component weight: steel up to 9 kg, aluminum up to 7 kg

- Minimum component weight: 0.05 kg for both steel and aluminum

- Maximum component dimensions: 250 x 350 mm

- Precision tolerance: ±0.2 mm

- Available materials: Stainless steel, alloy steel, carbon steel, aluminum alloys

Would you like to have something manufactured with this technology?

Find the peform location that realizes your challenge.

Find Location