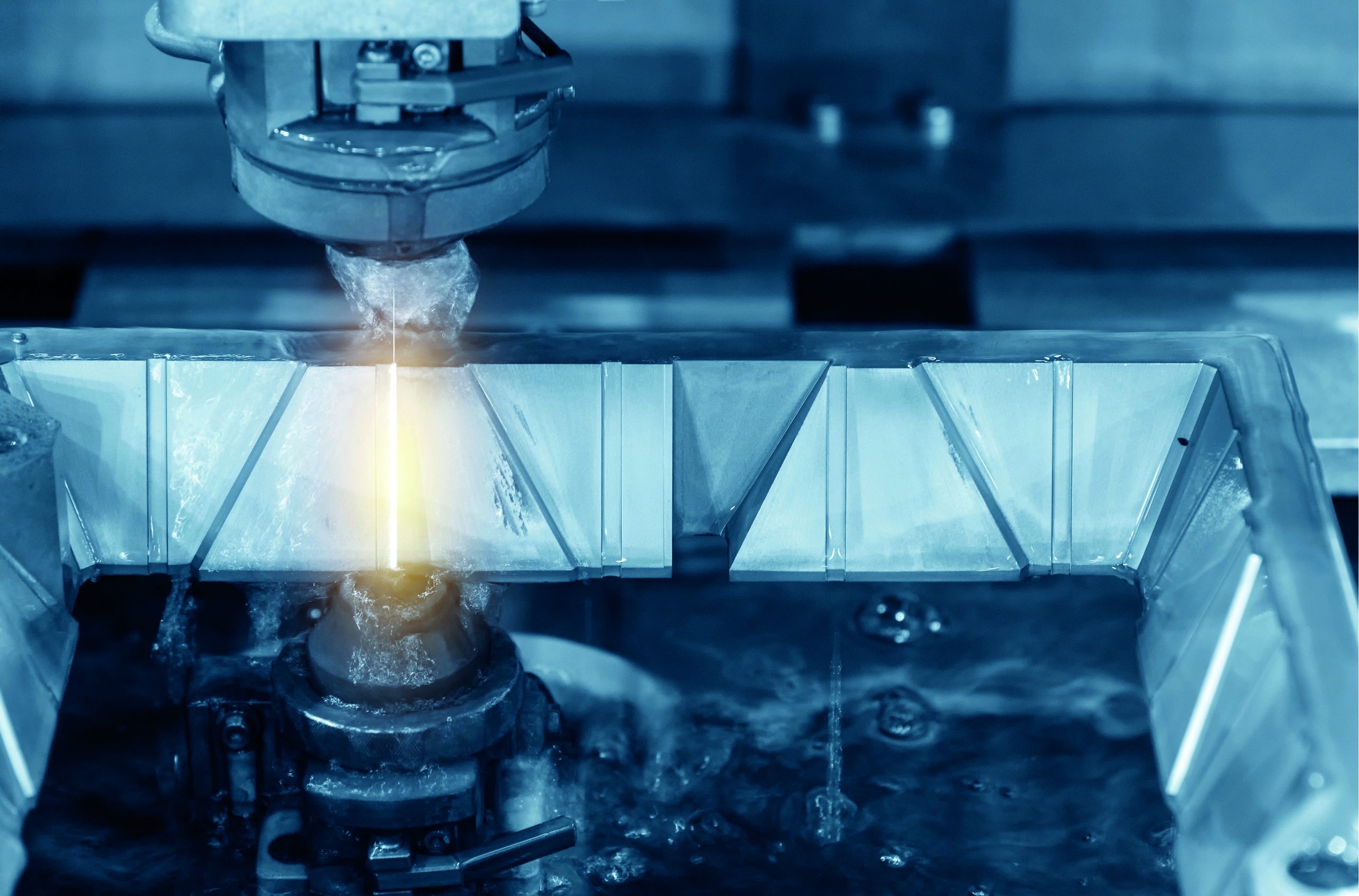

Experience unrivaled precision with wire EDM technology from peform.

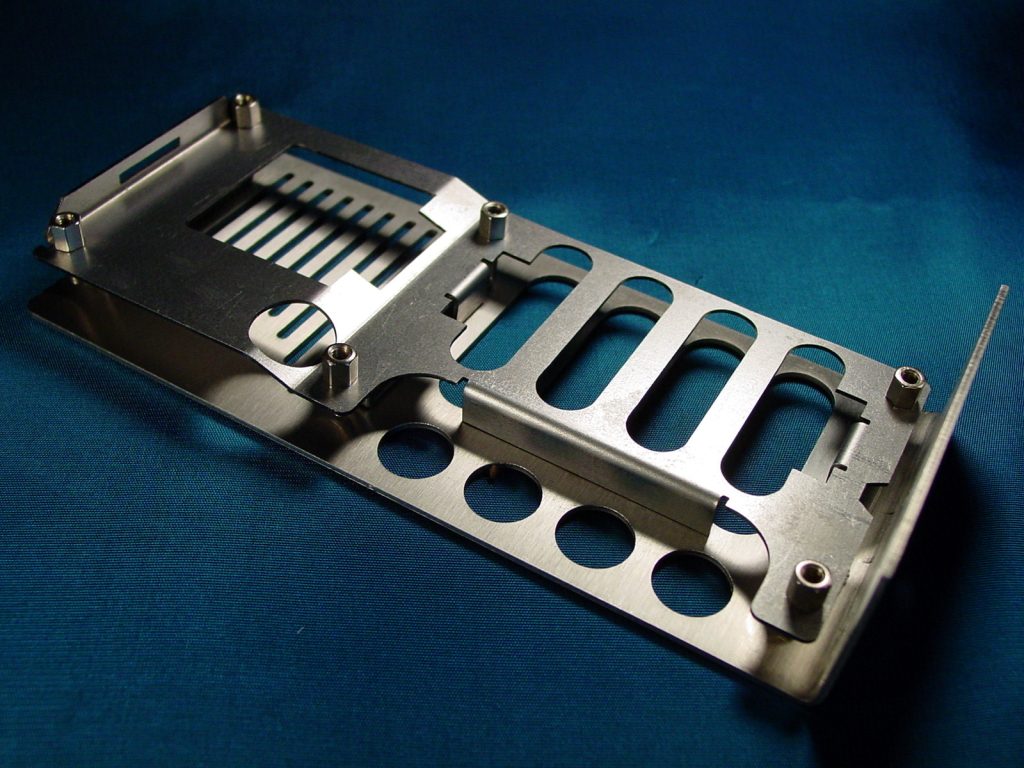

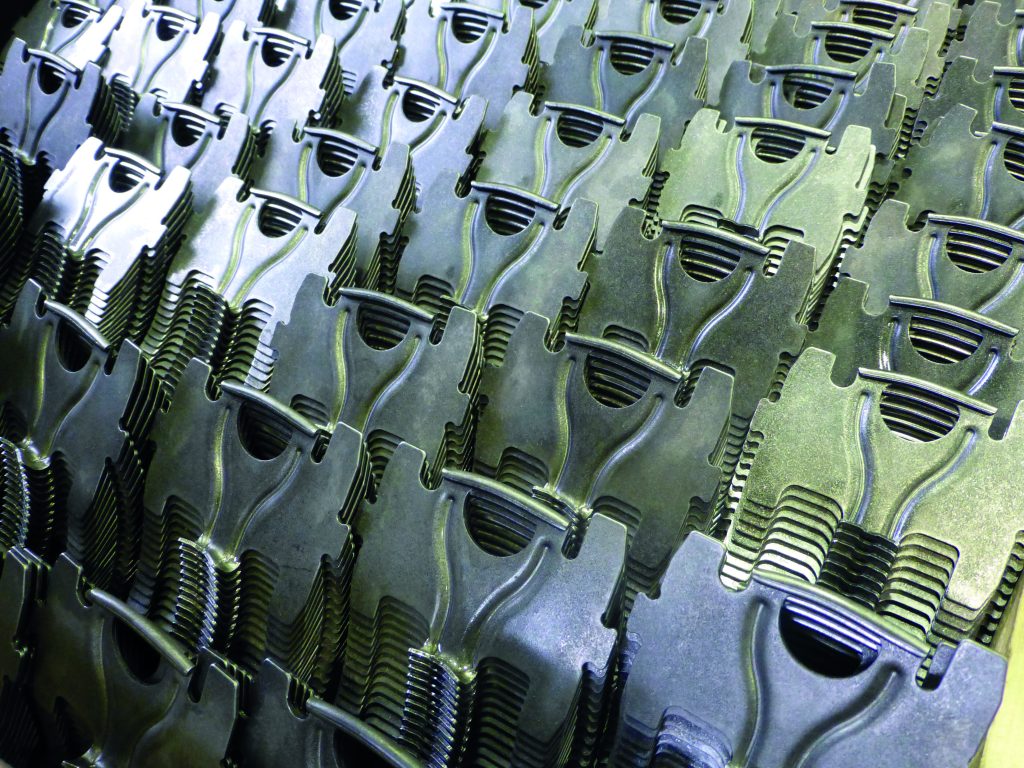

We specialize in the production of complex components, where turned and milled parts are further processed using wire EDM. Our technological flexibility is applied in industries such as mechanical engineering and the automotive industry worldwide.

Technology

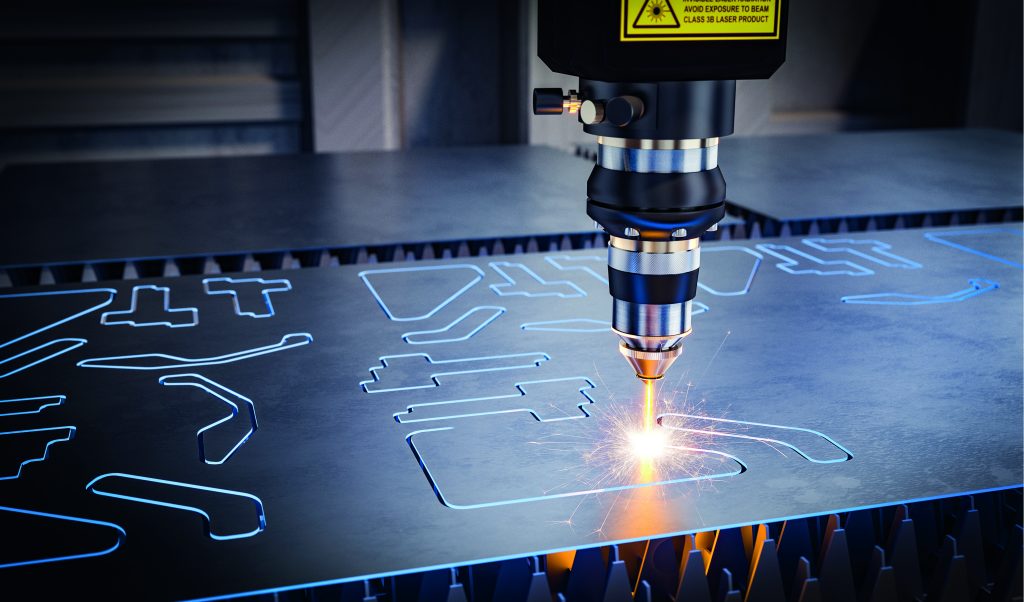

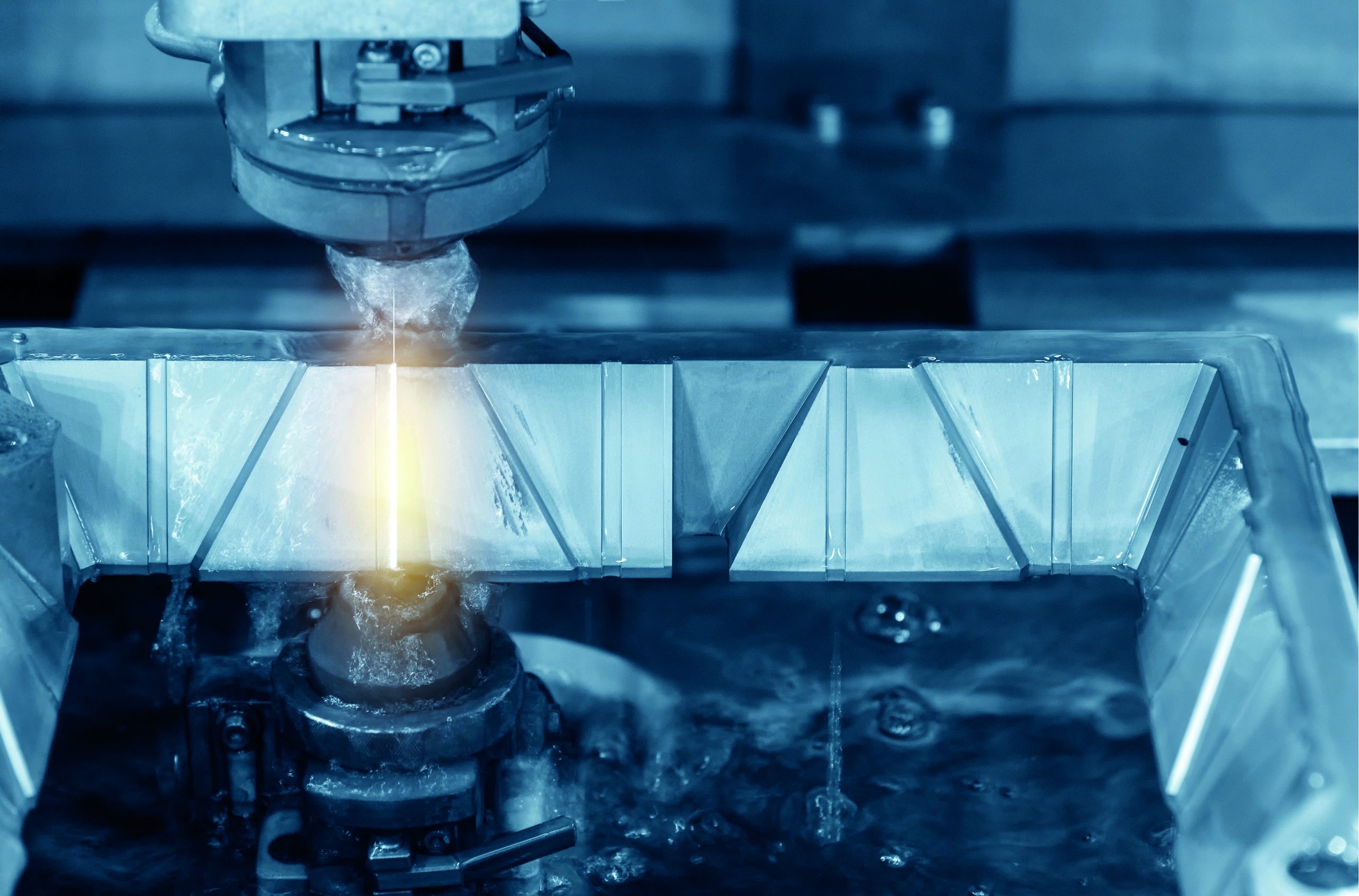

Wire EDM is an advanced cutting process that uses an electrically charged wire to erode conductive materials with precision. Our state-of-the-art wire EDM machines ensure exceptional accuracy in the production of complex geometries, combined with superior surface quality and stress-free material processing.

When precision matters most, wire EDM delivers.

This technology excels at cutting precise shapes, cores, and holes in the hardest conductive materials. Ideal for components with tight tolerances and complex internal features, wire EDM ensures consistent accuracy without compromising material integrity.

Why peform?

- Specialized expertise in complex geometries

- Ultra-precise cutting capabilities

- Stress-free material processing

- Consistent accuracy across multiple parts

- Ideal for hardened materials

- Superior surface finish quality

Main technical specification

- Our wire EDM infrastructure includes three advanced FANUC Robocut systems: Alfa-0iE, Alfa-1iC, and Alfa C600iA.

- These machines deliver precise, repeatable results for your most demanding wire erosion requirements.

Would you like to have something manufactured with this technology?

Find the peform location that realizes your challenge.

Find Location