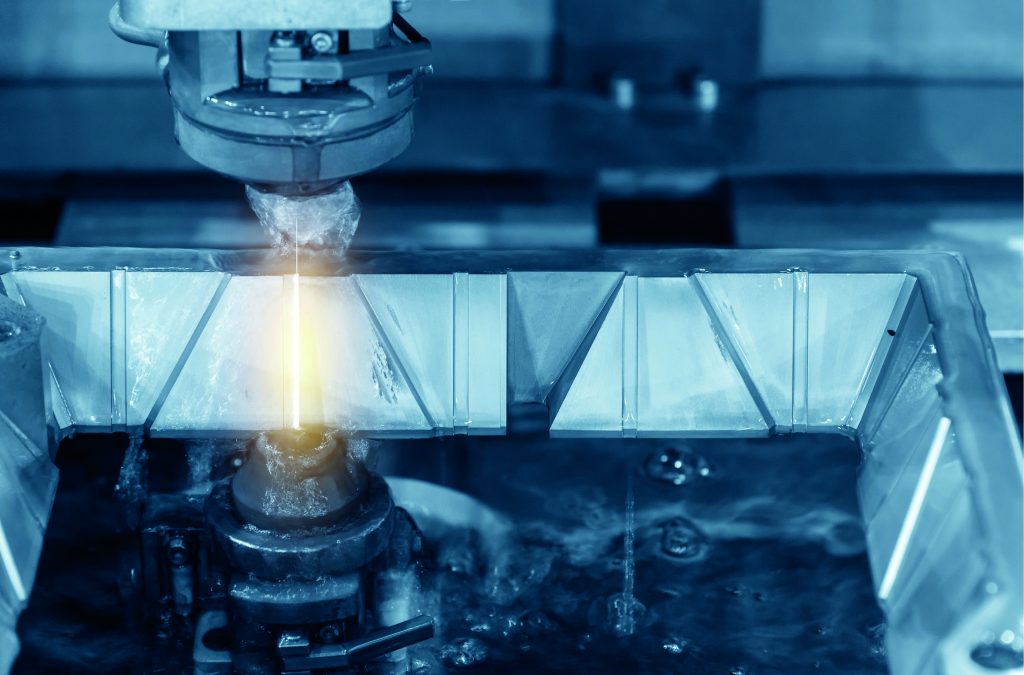

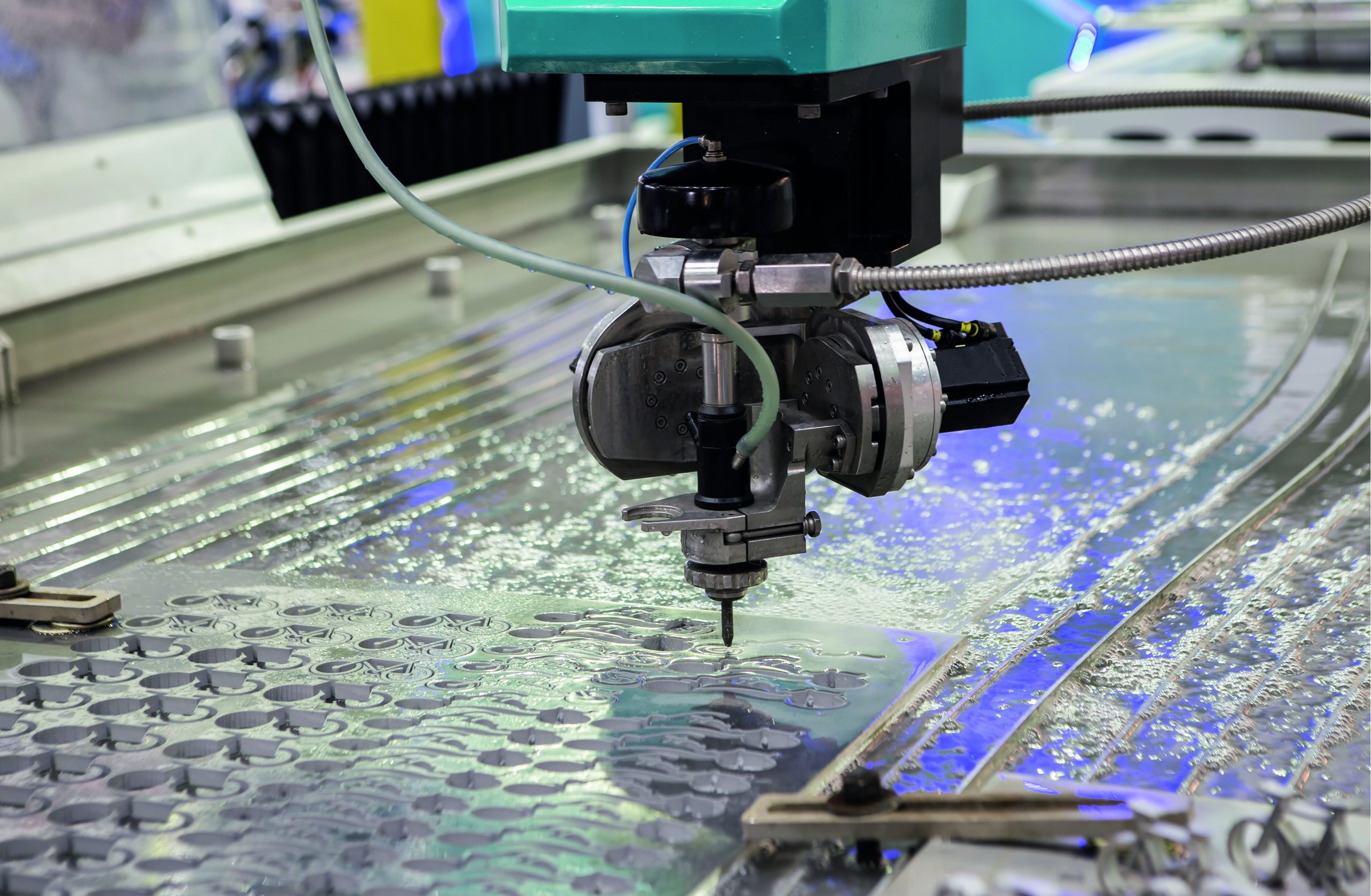

Unlock limitless possibilities with peform’s waterjet cutting technology.

Process an extraordinary range of materials, from metals to ceramics, glass, and stone, with precision up to 0.1 mm. Our advanced systems handle thicknesses up to 500 mm, transforming challenging materials into precisely crafted components with ease.

Technology

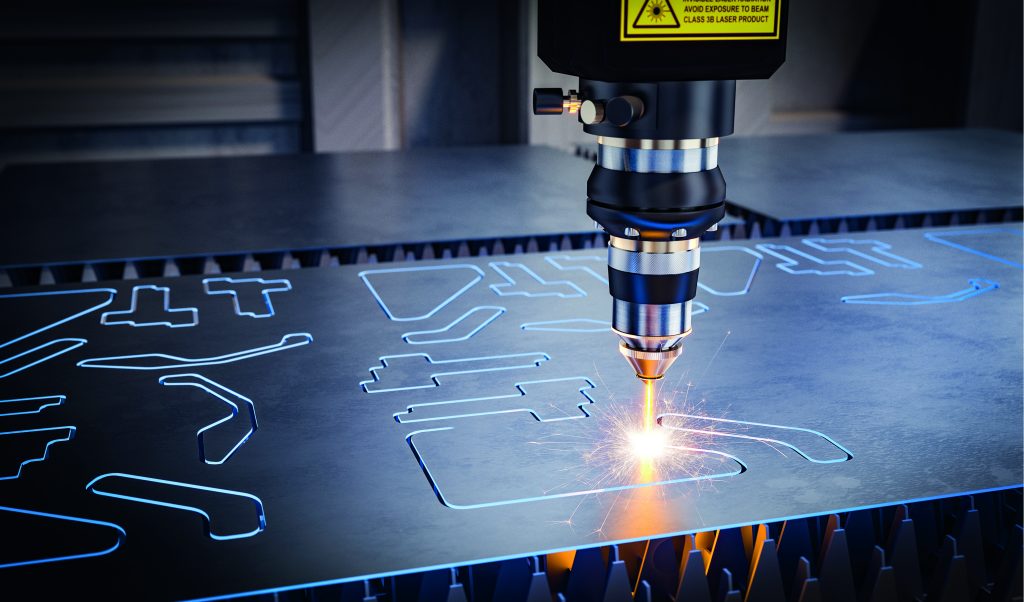

Our waterjet cutting technology provides precision cold-cutting for virtually any solid material. Metals, plastics, rubber, glass, stone, or ceramics – all are cut cleanly and accurately without thermal impact, preserving material integrity throughout the process.

Experience the advantages of cutting processes without heat input into the material.

Waterjet cutting ensures material properties remain intact while enabling complex angles beyond 90° cuts. With exceptional accuracy and surface quality, this method is ideal for water-resistant and thick materials requiring precision and efficiency.

Why peform?

- Unmatched material versatility across industries

- Superior cutting quality without thermal impact

- Capability for complex angular cuts

- Environmentally friendly processing method

- Cost-effective for thick materials

- Minimal waste through optimized nesting

Main technical specification

- Cutting pressure: 4,000 bar (400 MPa)

- Table dimensions: 2,000 x 4,000 mm

- Cutting speeds: Up to 10 m/min

- Precision: 0.1 mm with a minimum radius of 0.5 mm

- Material thickness: Up to 500 mm

Would you like to have something manufactured with this technology?

Find the peform location that realizes your challenge.

Find Location