Precision and innovation in advanced Test Gauge solutions.

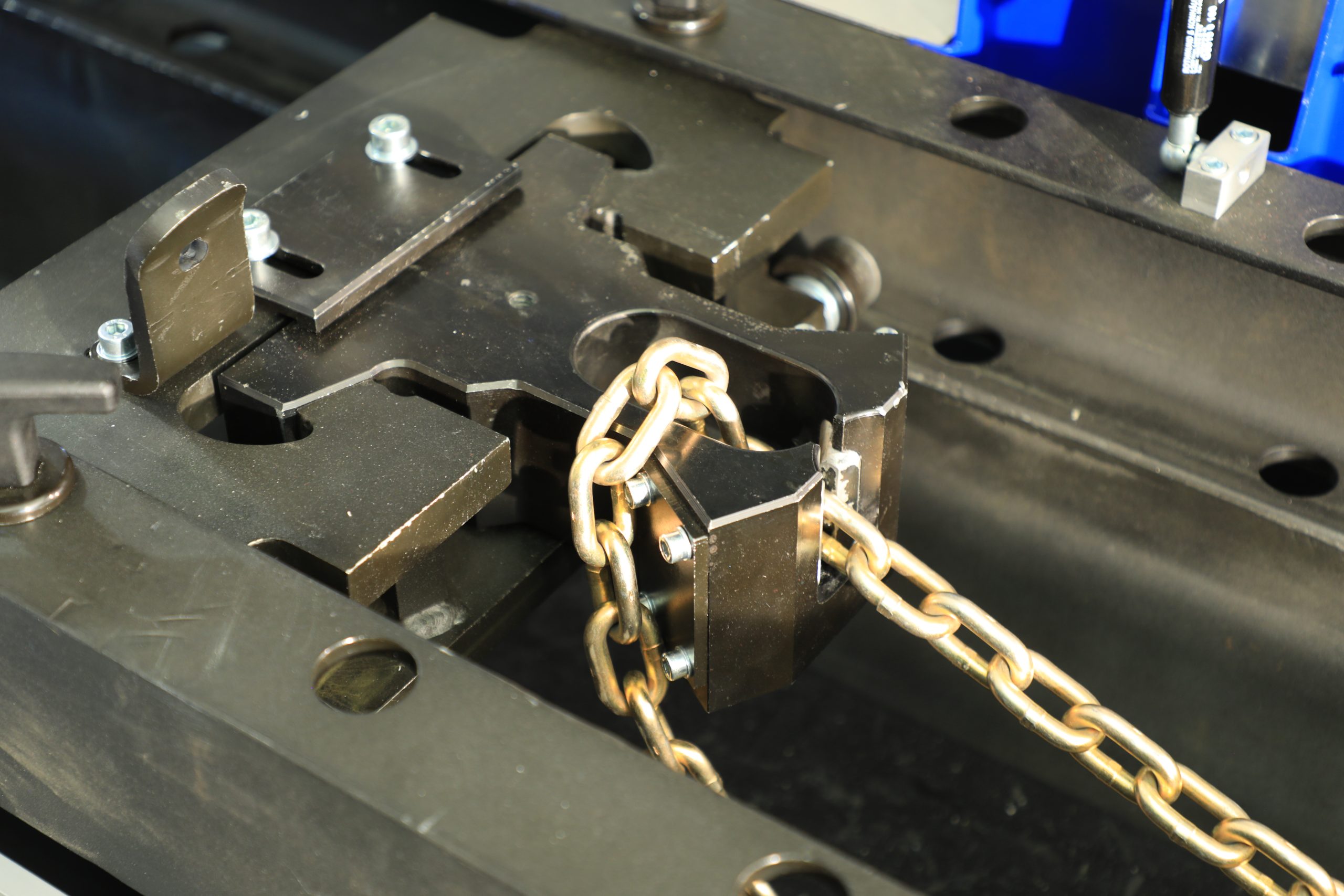

At peform, we develop automatic measuring and testing systems that verify component quality while integrating straightening and machining processes. Designed for safety-critical automotive structural components, our solutions ensure precision and reliability at every stage.

Technology

Our measurement systems employ advanced sensor technology and precision mechanics for automated quality control. Capable of handling aluminum, magnesium, and other die-cast components, these systems integrate straightening capabilities with high-precision measuring tools. Multi-axis measurement ensures comprehensive component verification in real-time production environments.

Benefits and application

Our measuring devices seamlessly integrate into production processes or serve as reliable solutions for end-of-line inspections, ensuring consistent component quality. By using our systems, customers benefit from enhanced manufacturing efficiency, minimized errors, and guaranteed compliance with safety standards – providing a competitive edge in producing high-precision structural components.

Why peform?

- Realization of customized tactile and camera-based measuring systems

- Development of specialized testing technologies that perfectly support product and process requirements.

- Individual approaches for safety-critical components

Our portfolio includes:

- Takt time-neutral testing and measuring devices (end-of-line)

- Integrated testing and straightening device

- Quality testing for complex cast parts

- Comprehensive data collection to ensure traceability

Unlock new potential in your manufacturing process with innovative engineering solutions!

Talk to our experts and find the solution tailored to your needs.

Get in touch