Combine precision engineering with manufacturing innovation at peform.

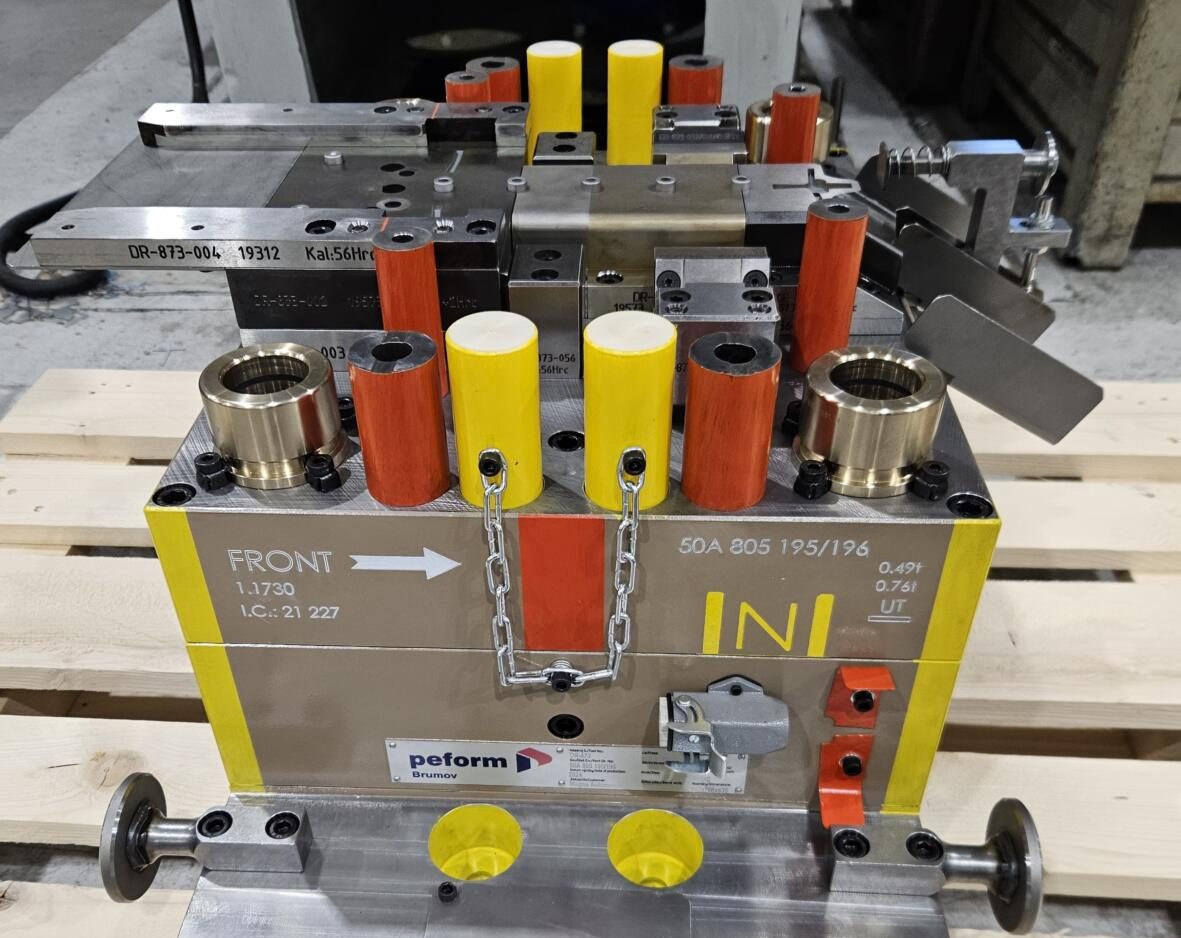

Our tools and fixtures for pressing and punching transform complex design challenges into high-performance tools. From follow-on and transfer tools to specialized bending and punching tools, we deliver solutions that advance your production and meet the highest industry standards.

Technology

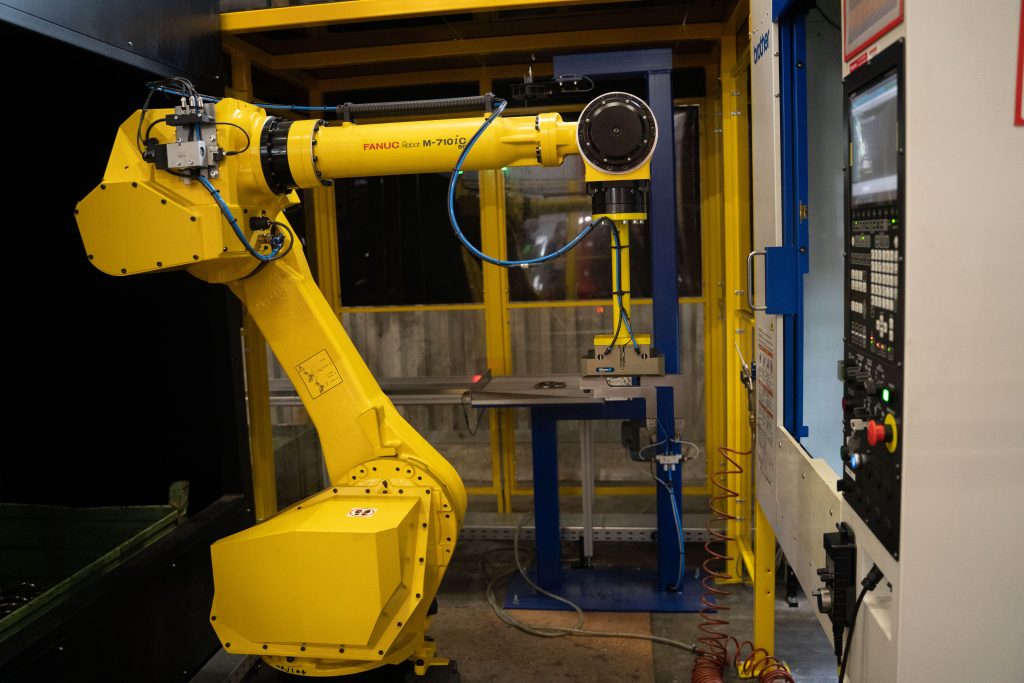

Using advanced 3D CAD software like SolidWorks and Logopress3, paired with measurement technologies such as Carl Zeiss Contura G2, we engineer stamping dies with unmatched accuracy. Our digital-first approach ensures perfect alignment between design and execution for seamless results.

Simplify complexity with full-service stamping die solutions.

We manage every phase of your project—from design and prototyping to assembly and maintenance. Our comprehensive toolkit reduces production complexity and enhances operational efficiency, providing the precision and reliability your manufacturing requires.

Why peform?

- Pressing and stamping tools are the core competence of peform Brumov

- Nearly 80 years of specialized tooling expertise

- End-to-end service from concept to maintenance

- Prototype die and forming part production

- Unmatched precision across multiple die types

Main technical specifications

- Maximum tool dimensions: 2000 x 800 x 600 mm

- Maximum tool weight: 3,000 kg

- Supports multiple die configurations

- Precise measurement and quality control

- Adaptable to complex manufacturing requirements

Unlock new potential in your manufacturing process with innovative engineering solutions!

Talk to our experts and find the solution tailored to your needs.

Get in touch